Pig industry is one of the key industries providing the world food security. It satisfies the need of billions of people across the globe in protein whereas the pig meat is the leading meat consumed by the humankind.

The worldwide production of the pig meat is over 110 million tons per year. The leading pig meat producers are China (over 53 million tons), the European Union (over 23 million tons) and the USA (around 11 million tons). Polish pig meat production constitutes 8,5% of EU-28 total.

The manual labour still deeply penetrates the majority of all processes related to the pig fattening. In Europe its cost is on the rise. However, the effectiveness of the human intervention in the pig fattening has its own limitations. Humans are susceptible to make mistakes during pig weighing or counting. They cannot easily detect early signs of animal diseases when pig herds are large. Their presence in pig pens causes stress and negatively influences the pig fattening.

The productivity and ultimately the cost of the pig meat production are shaped by a number of factors including:

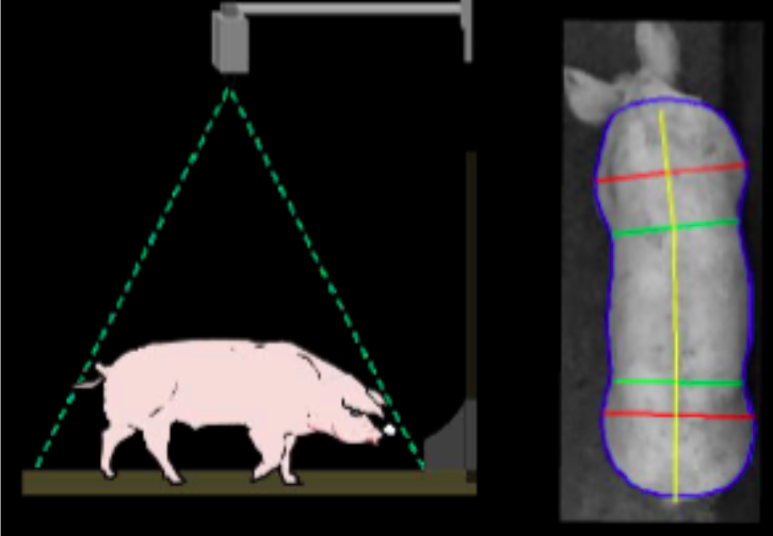

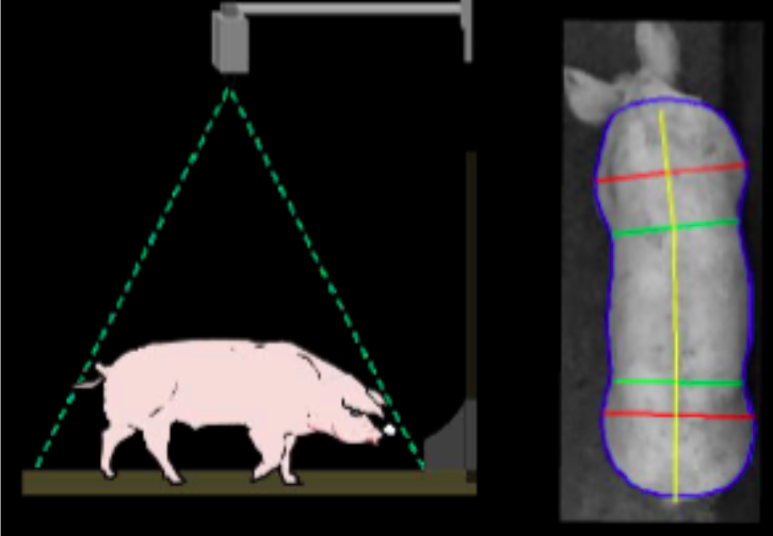

In order to monitor the effectiveness of the pig fattening, optimal feed conversion should be achieved. It requires regular measurement of the weight.

In order to weigh pigs on the farm, animals must be relocated to the weighting chambers. As a rule, it requires the manual work of two people and several minutes per one pig.

Animal stress negatively impacts the fattening process. It can be caused by any human intervention, the tail biting etc. While not perceived by humans, human intervention leads to the animal stress and drastically lowers the speed of fattening process, thus making it less economically viable.

In order to prevent the tail biting, the behaviour of animals should be constantly monitored.

Overall, the effective pig farm management needs precise prediction of the output of fattening process.

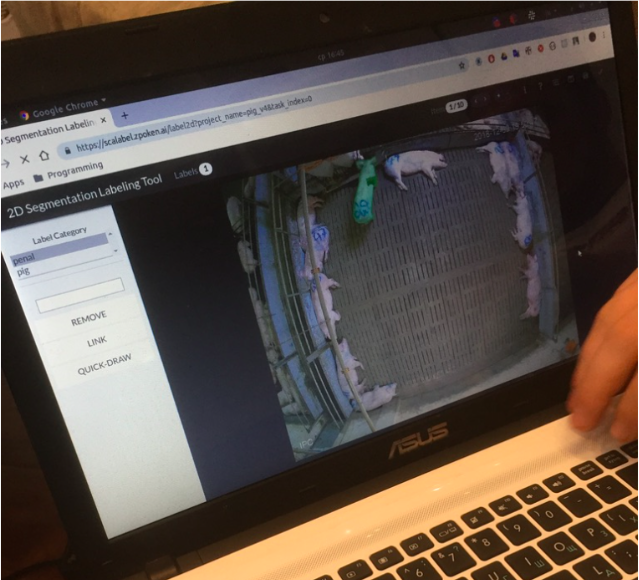

We applied Machine Learning, Machine Vision, Pattern Recognition, Big Data Analysis and Artificial Intelligence to provide farmers with crucial information: head count, animal weight measurement and prediction, tracking efficiency of the feed conversion and behavioural changes etc. We use the technological innovation by Nebesky LTD, Hong Kong.

Automated system consisted of cameras, ML \ AI algorithms and cloud infrastructure. It significantly reduced the human involvement in a number of key procedures related to pig fattening.

The project results minimized the human intervention during pig weighing, monitoring pig fattening and disease monitoring. The project brang about the automated system of pig counting, weighing and monitoring based on the machine vision and learning.

Copyright © codective